TUBEdek™ Lamella Settlement (2016)

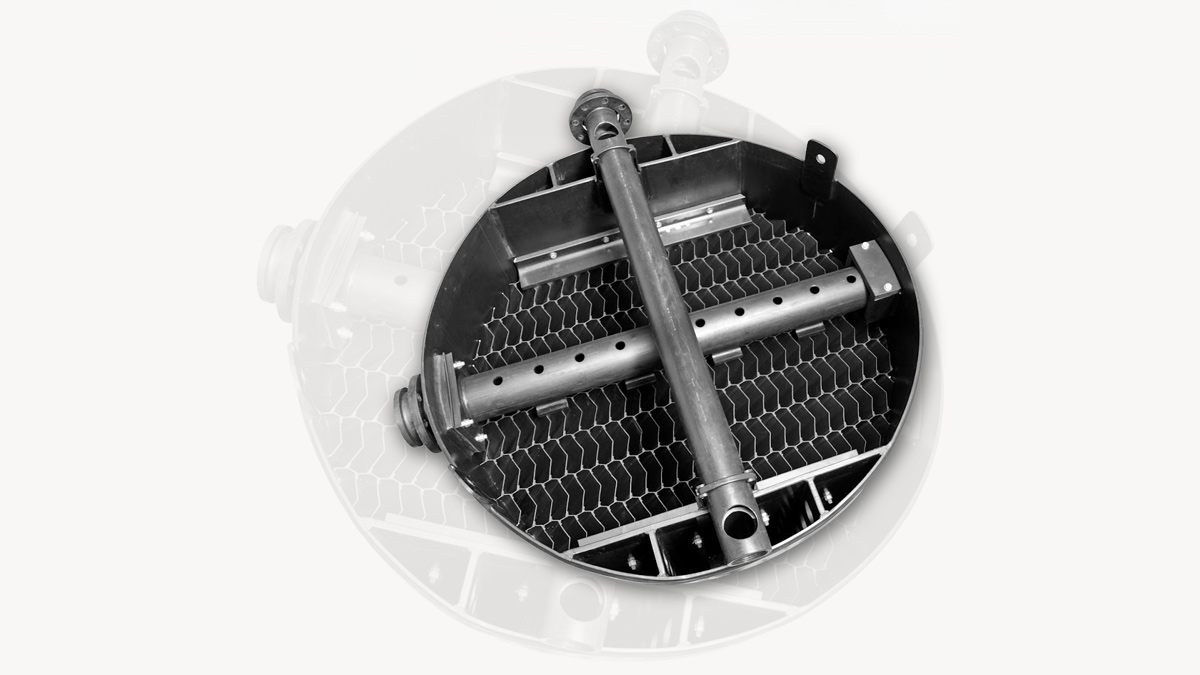

2H Water Technologies TUBEdekTM in tank

By 2050, total water demand in England and Wales is expected to increase by 35%. Per predictions by the Office for National Statistics, the UK population will reach 71.4 million by 2030, and 78.4 million by 2050. Climate change projections suggest summer temperatures will increase while rainfall will decrease leading to an 80% reduction in gatherable rainfall. As climate change, groundwater depletion and population growth heap additional pressure on finite freshwater resources, treating wastewater to potable standards is gaining recognition as a sustainable method of supplementing water supplies.

TUBEdek: the solution to every ‘tough-to-treat’ potable water challenge

Industry commentators often use the phrase ‘toilet to tap’ which, while not entirely accurate, encapsulates the challenge of converting contaminant-laden, ‘tough to treat’ wastewater into potable water that meets the strictest regulatory standards.

The industry-leading range of TUBEdekTM lamella separation tubular settlers from Enexio 2H Water Technologies play a vital part in the potable water treatment by removing solids from the raw water intake during the settlement process. At this point, there will be several thousand milligrams of sludge, sand and silts per litre of surface water. In addition, the chemical precipitation and flocculation processes produce significant amounts of solids.

The most economical method of removing this type of pollution is parallel plate sedimentation as used in TUBEdekTM.

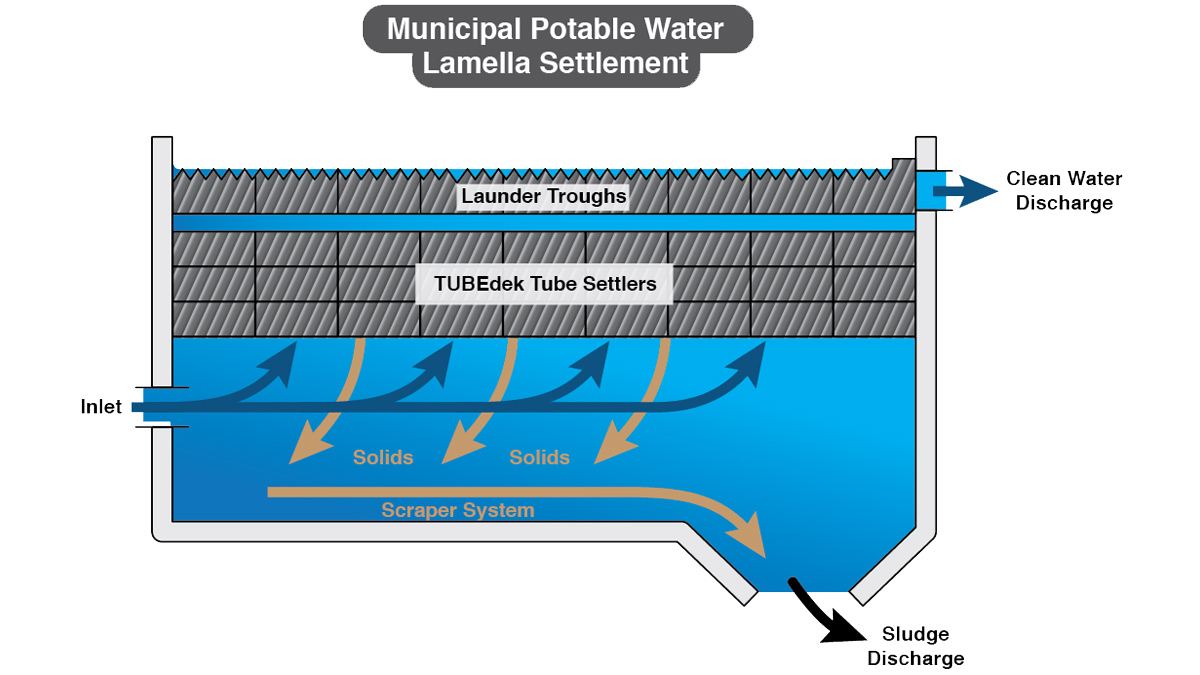

2H Water Technologies municipal potable lamella settlement

Enexio 2H Water Technologies municipal potable lamella settlement

Biological processes: the solution to surface pollutants

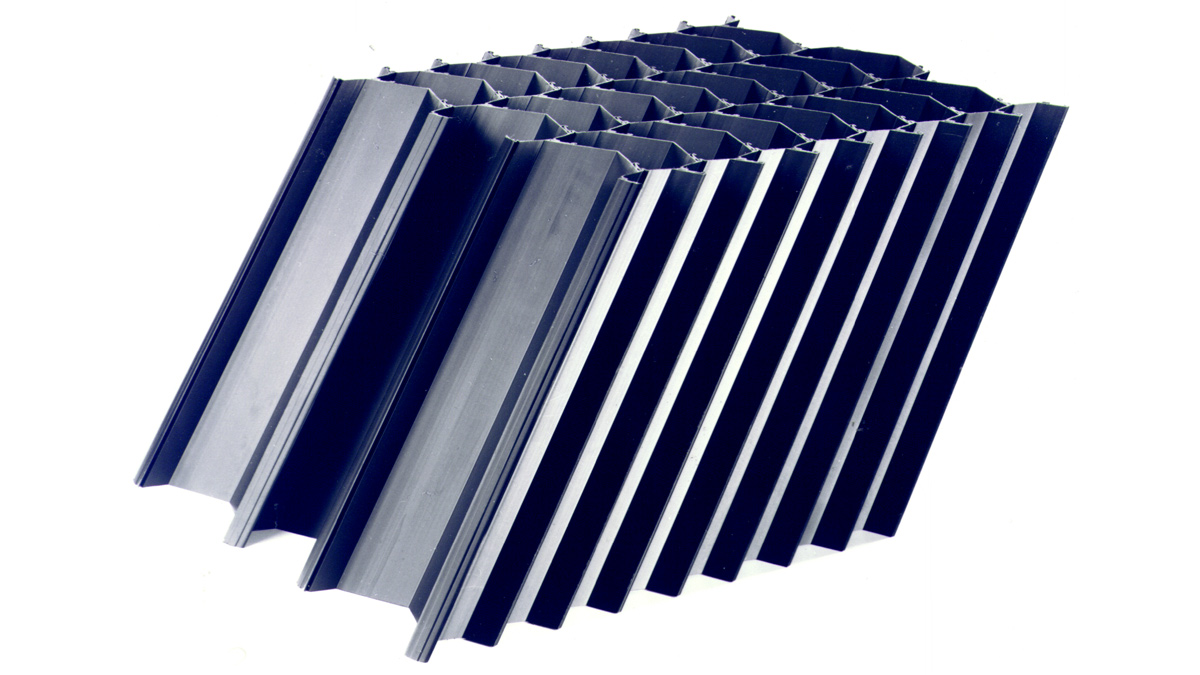

TUBEdekTM lamella settlement fills utilise a chevron plate sedimentation process which is a more effective method of separating solids from liquids. The uniform configuration and inclined angle of the tubes encourages laminar flow for efficient solids separation whilst the ‘v’ shape encourages a more even discharge of solids to the settlement zone below the TUBEdekTM modules.

The tubes are designed to adapt easily to any process design requirement by varying the inclination, length of tubes and module sizes.

Because TUBEdekTM uses a parallel plate sedimentation process, multiple plates can be housed in a single, cost-effective tank and not, as with many other products, in lots of large and expensive tanks.

The tongue and groove design is another unique aspect of TUBEdekTM. The design not only simplifies assembly – a significant bonus for large schemes where TUBEdekTM modules can be built close or even adjacent to the main site – but also ensures exceptional mechanical strength.

2H Water Technologies TUBEdekTM

Enexio 2H Water Technologies TUBEdekTM

TUBEdek at-a-glance

The TUBEdekTM range includes certified products for all potable water applications from Highland whisky to tap water.

- Hydraulic parameters improve efficiency (Reynolds number).

- Equidistant channels for full sedimentation.

- Special support systems avoid impact on the process.

- Up to 15 sedimentation planes above one m² of base.

- Manufactured in polypropylene which is suitable for all potable water applications.

Nitrogen removal

Surface water can be polluted by a wide range of contaminants including agricultural, industrial or municipal discharges of nitrogen (ammonia or nitrate). Biological processes – such as nitrification and denitrification – are effective in removing this type of pollutant. However, nitrification and denitrification need carriers with surfaces to establish and maintain the biomass. Enexio 2H Water Technologies supplies a large variety of such carrier materials including the BCN-range for moving bed or BIOdek KFP319 for structured media reactors.

Iron: oxygenation and removal

TUBEdekTM packing is designed to achieve an intense mixture of water and air to bring the oxygen content up to saturation point and enable oxidization of the dissolved iron. The iron precipitates either in or below the packing at which point it can be removed by filtration or sedimentation.

Lamella settlement

Lamella settlement

Case study: South East Water, Keleher WTW, Bray

Every TUBEdekTM installation is a customised solution, purpose-built to deliver the customer’s objectives of improving processing efficiency while treating heavier loads and higher effluent flows – all while meeting tighter discharge consents.

South East Water is one such customer and was the first UK municipal water company to go live with Enexio 2H Water Technologies’ Drinking Water Inspectorate Reg 31 approved TUBEdekTM FS41.50PP product at its Keleher WTW in Bray, Berkshire. Almost immediately, the Keleher plant recorded a significant increase in productivity and operational reliability.

South East Water provides drinking water to over 2.1 million customers in an area which encompasses Kent, Sussex, Surrey, Hampshire and Berkshire.

The region has relatively low rainfall compared to the rest of the UK. It also has a dense and fast growing population with a higher per capita rate of water consumption than other comparable areas of the UK. It is no surprise that region has been classed as ‘seriously water stressed’.

South East Water is continually developing new water resources. In its latest Water Resources Management Plan (WRMP), issued in 2015, the company committed to investing £400 million in developing new water sources.

TUBEdekTM lamella settlers

TUBEdekTM lamella settlers

One of the largest projects in South East Water’s five-year programme of work was the extension to Keleher WTW. Located in Bray, Berkshire, the works currently supplies drinking water to 2.1 million customers in Berkshire, Surrey, Hampshire, Sussex and Kent, and treats 30 million litres of wastewater per annum.

Brian Steventon, Project Manager at South East Water, said:

“TUBEdekTM met all our objectives, most notably in removing the bottleneck that restricted output in the previous horizontal lamella clarification system. Within months, we were seeing average flows between 30Mld and the maximum 45Mld which was a significant improvement on the 22Mld we achieved with our previous system.

“In addition, the upgrade project provided an opportunity to improve process control and increase the throughput of the clarifiers from 25ML/d to 40ML/d.

“South East Water considered several alternatives to TUBEdekTM. We looked at replacing the existing horizontal lamella clarification system but rejected that option as it wouldn’t provide the required improvements in production capacity. We also investigated a stainless-steel alternative which seemed effective but was very expensive.

“We chose TUBEdekTM because it was the best match for our requirements; price, performance and DWI Reg 31 accreditation. We were confident that TUBEdekTM could deliver the required improvements in performance – notably in hazen velocity – and we had the reassurance that comes from DWI accreditation.”

This paper was prepared by Richard Manning, Managing Director at Enexio 2H Water Technologies. For more information visit www.2hwatertechnologies.co.uk, call 0845 0039 114 or email sales@2hwatertechnologies.co.uk.