Aarsleff Ground Engineering Ltd

Detecting Hydrocarbon Contamination (2023)

MS1800 inside a cabinet - Courtesy of Multisensor

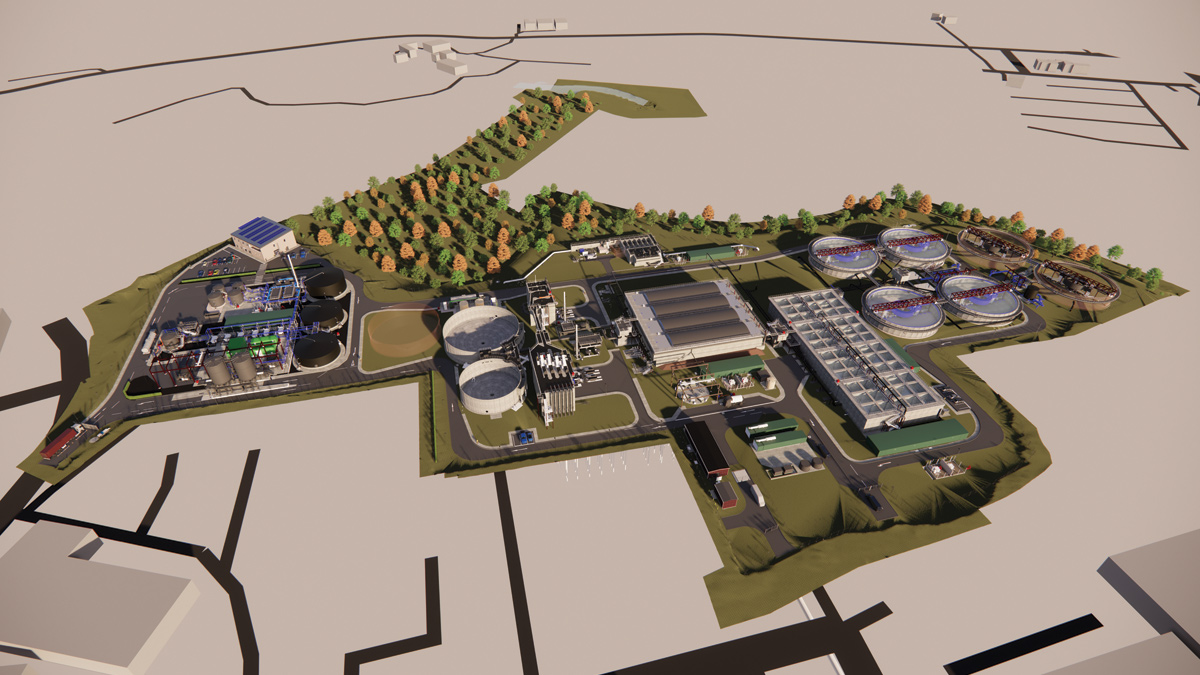

A municipal wastewater treatment plant in Poland was struggling with a persistent issue; hydrocarbon contamination in the wastewater coming into the plant. The plant had not been designed to deal with high levels of hydrocarbon contamination, such as that coming from untreated industrial wastewater, which meant that every time there was a contamination event in the sewerage system, the WwTP performance was affected and, in the worst case, contamination was also released into the environment and regulations were broken.

Moreover, the activated sludge performance was affected and, if the levels were high enough, this could lead to the process needing to be stopped altogether.

The solution

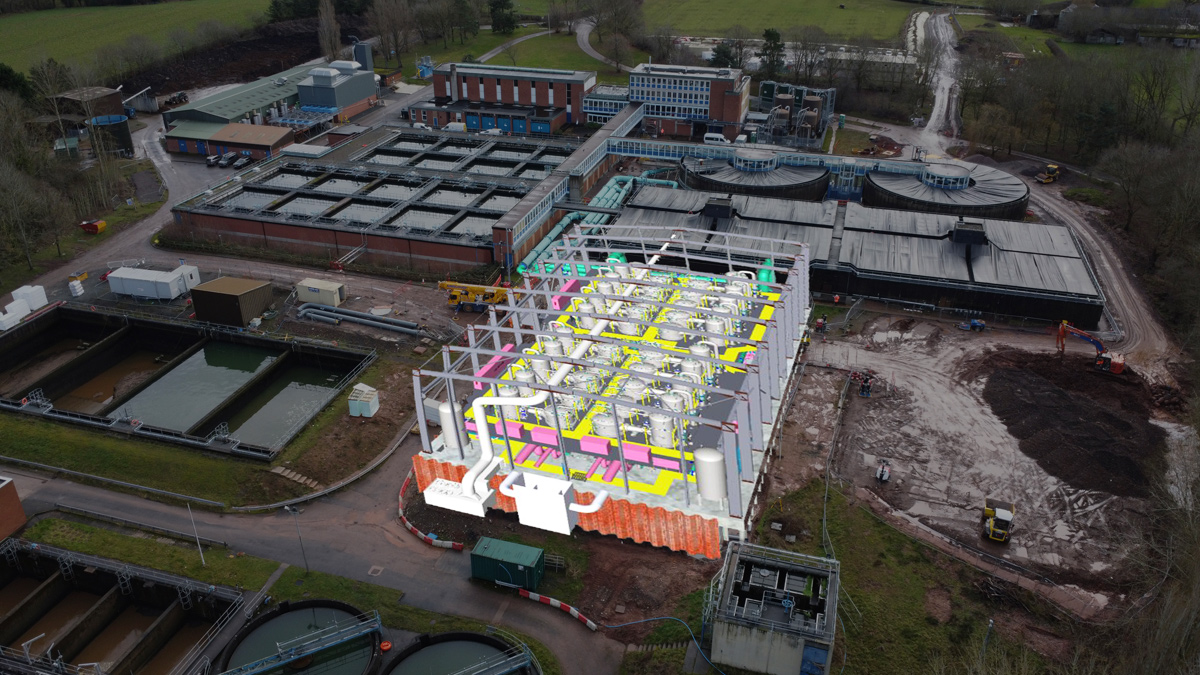

In the spring of 2022, Multisensor Systems Ltd’s Polish distributor (GREMES) was contacted to review options and following preliminary discussions, engineers at GREMES proposed an MS1800 VOC gas analyser to be installed directly above the sewage line.

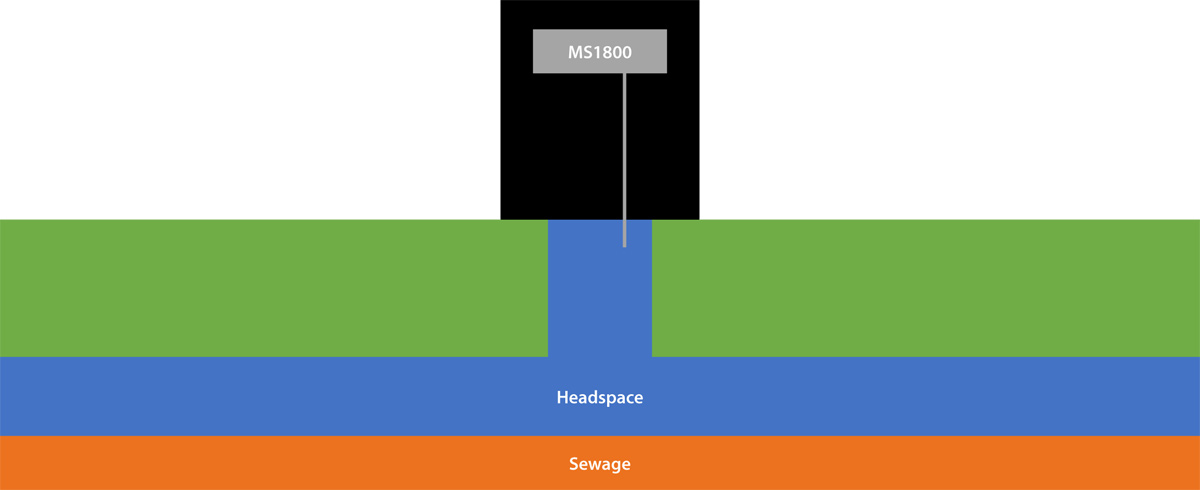

The MS1800 is designed to monitor VOC concentration in the headspace above the wastewater and from this, calculate the hydrocarbon contamination within the wastewater.

Installation diagram – Courtesy of Multisensor Systems Ltd

Installation diagram – Courtesy of Multisensor Systems Ltd

The instrument was installed in a temperature controlled cabinet, ensuring that the analyser’s technical specifications were met in the open air. The system was linked to a remote control system to provide a live data feed and allow the user to generate reports and alarms.

The site selected for the installation is a wastewater pumping station, the last before the intake of the WwTP. This has made the installation more straightforward and, with a constant flow of wastewater, reduced the risk of H2S build-up that could be detrimental to the longevity of the system.

The data

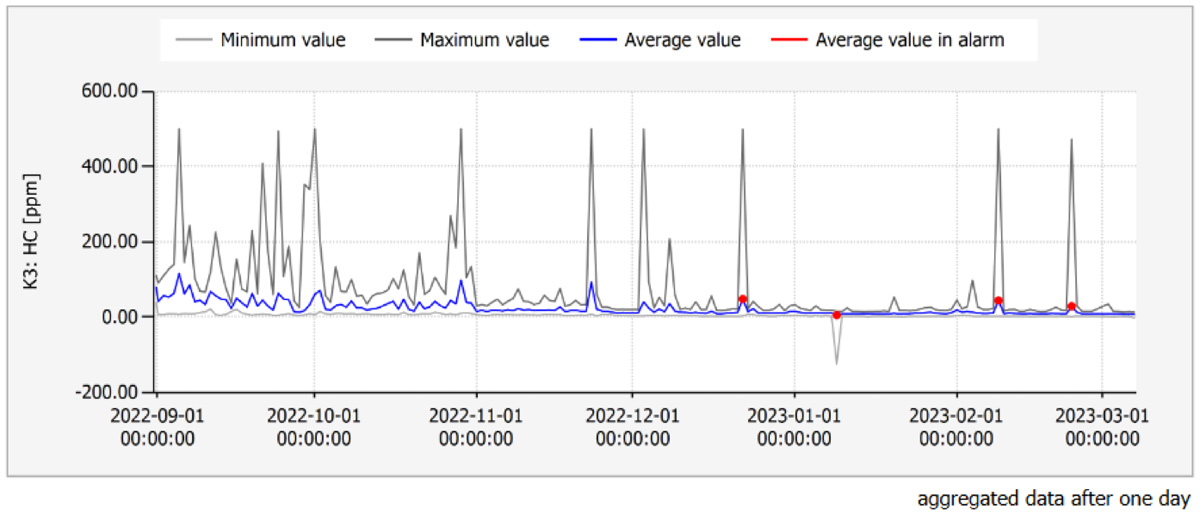

The instrument was installed in July 2022 and, aside from a brief pause, has (at the time of writing – April 2023) been working non-stop ever since.

The data below shows how the instrument has clearly identified several peaks over the course of several months. These peaks have been positively associated with contamination events and corroborated by analysis carried out by the WwTP.

After several months of testing the client is extremely satisfied with the results and is in active discussions with GREMES to develop the next phase of the project that will consist in deploying a network of analysers across strategic points in the sewerage network.

Graph showing hydrocarbon readings from September 1, 2022-March 1, 2023 (graph produced by independent software) – Courtesy of Multisensor Systems Ltd

Graph showing hydrocarbon readings from September 1, 2022-March 1, 2023 (graph produced by independent software) – Courtesy of Multisensor Systems Ltd

Uses

The MS1800 in this installation will be mainly used to identify contamination events and locate the source of pollution but also to protect the WwTP by diverting industrial wastewater for separate treatment.

Strengths

This system allows the accurate on-line monitoring of hydrocarbon contamination in the sewage system, without touching the water, designing out of the equation words such as ‘cleaning’, ‘maintenance’ and ‘filtering’.

Conclusion

As can be seen from the data above, the MS1800 is an excellent solution for the monitoring of hydrocarbon contamination in any sewerage network.

If your operations are suffering from unexpected hydrocarbon contamination at the raw wastewater intake of your WwTP, you can get in touch and discuss your case with our consultants.

This article was prepared by Multisensor Systems Ltd

Alexandra Court | Carrs Road | Cheadle | SK8 2JY

P: +44 (0)161 491 5600 | E: info@multisensor.co.uk | www.multisensor.co.uk

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Senior Process Engineer (67418BR)

| Location | North East | Durham | Discipline | Project Delivery | Design |

| Contract type | Permanent | Job reference | 67417BR |

| Work pattern | Full-time | Recruiter | Lauren Hutchinson |

| Sector | Water | Wastewater | Interested? | APPLY HERE |

Mott MacDonald Bentley (MMB) is the design and build unit of global engineering consultancy Mott MacDonald. Our Design Leads are responsible for large projects or programmes of work, managing between one and three Project Leaders as well as specialist multi-discipline designers to deliver for our clients.

As a Senior Process Engineer, you will be accountable for the design of a programme of water and wastewater infrastructure and non-infrastructure projects through the outline and detailed design, construction, commissioning, and handover. You will be responsible for building a project team comprised of electrical, mechanical, civil, and process designers who will support your Project Leader. You will provide the direction and co-ordination to enable your project teams to complete the designs in accordance with the specifications, to programme and within budget.

This role will provide you with the opportunity to develop your technical and management skills, grow your professional network, and provide you with excellent long-term potential to advance your career.

Candidate Specification

- Chemical Engineering or relevant Process Engineering related degree, preferably chartered.

- Experience and understanding of water and/or wastewater unit processes and treatment plant, with experience of delivering process design for wastewater projects.

- Experience of HAZOP studies as chair or team member would be advantageous

What we can offer

At Mott MacDonald Bentley you will be offered a competitive salary which is commensurate based on your experience. Our core benefits include:

- Pension matched up to 7%

- Competitive annual leave and the option to purchase additional annual leave

- Life assurance

- Enhanced parental leave

- Annual professional institution subscription costs

- Flexible benefits to suit you, including cycle to work scheme and interest free season ticket loans