Cotswold Valves

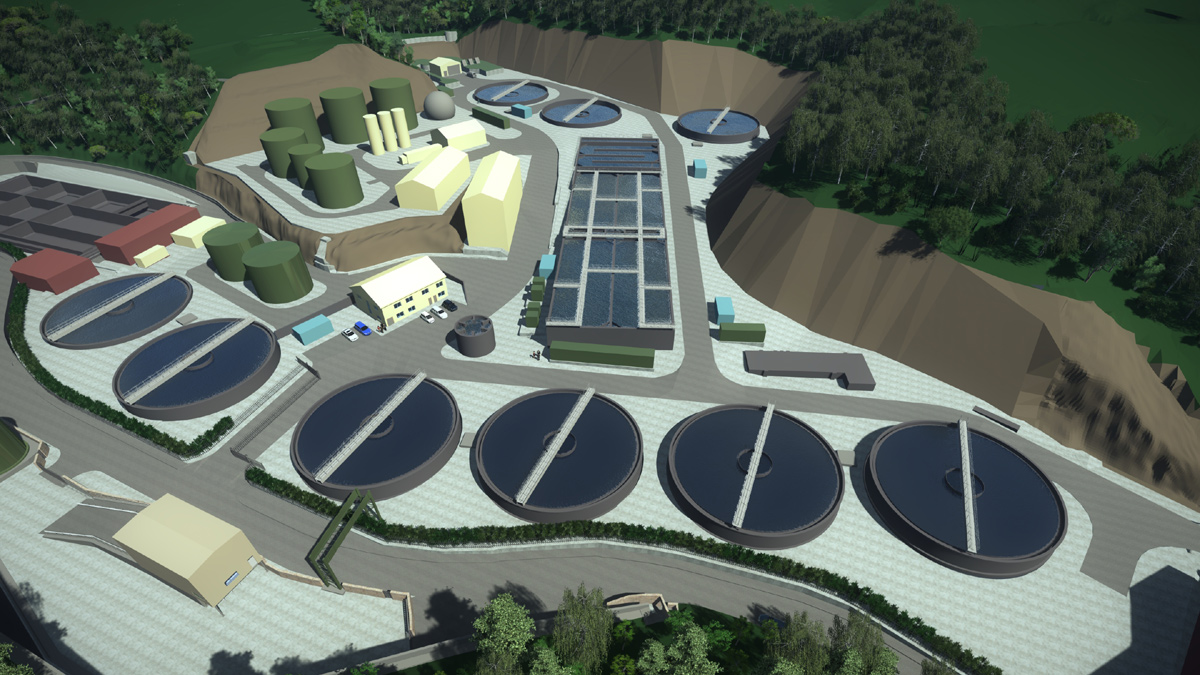

Birmingham Resilience Project

The team at Flow Control have significant experience of dealing with water utility companies including Welsh Water and its contract partners. During the last 20 years the team have secured and supplied valve framework to all water utilities in the United Kingdom. The team have been responsible for supplying over £100 million of valves, actuators and flow control equipment including major infrastructure works where our expertise has been instrumental in the successful implementation of new works.

The team has worked closely with Welsh Water supplying valves and penstocks to sites throughout the territory including Prioress Mill, Portis LLechryd, Cog Moors, Pontsticill, Bryn Cowlyd.

The team members are experts in either a valve category or process and have been responsible for changing the way the valve industry interacts with its customers. The emphasis of the business is on partnering with customers to deliver the customer’s vision and assist in achieving regulatory and business targets. Consistently offering independent, impartial advice and selecting the right product or process for a job we offer bespoke solutions to customers requirements. Our research and development activities have seen both improvements to existing products and the introduction of new products.

Our product selection consultancy is available free of charge to customers.

Key to selecting the correct valves is a detailed understanding of the operating specifics of each valve category and how they interact with other products and processes. This has been developed by years of working in the valve industry. We use a combination of sizing programmes and testing to enable valve selection. All employees at Flow Control have over 25 years experience within the field. We employ individuals with actuation experience including ex-rotork employee who spent 18 years at Rotork as a field service engineer and sales engineer.

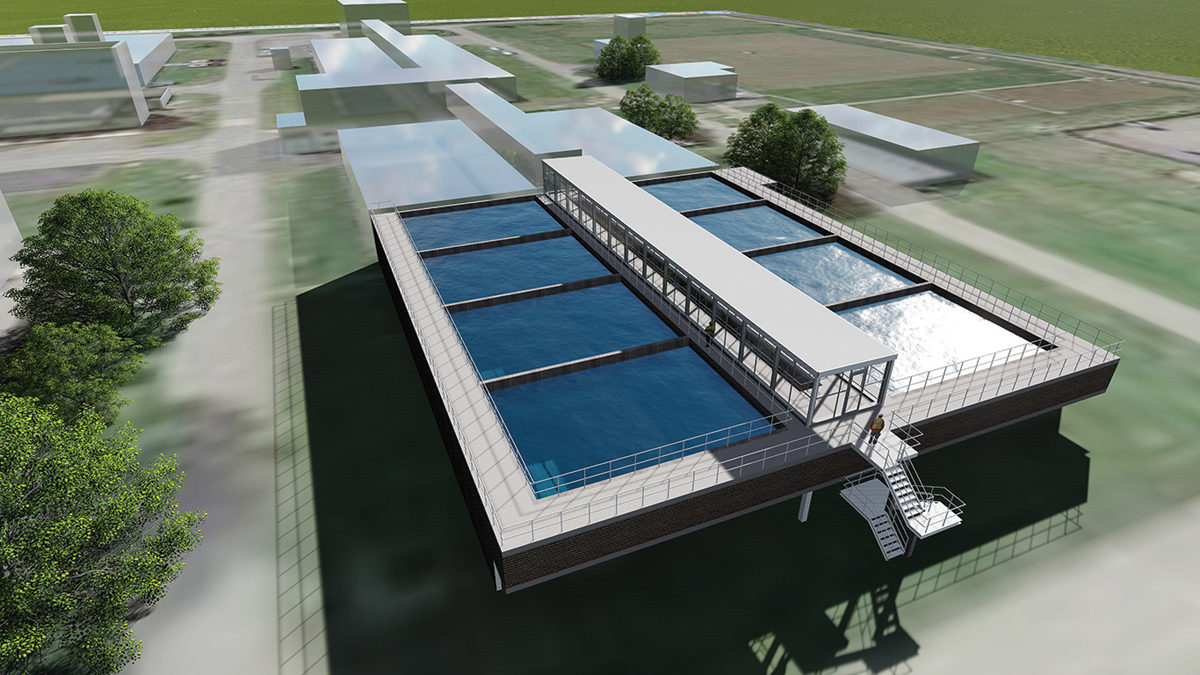

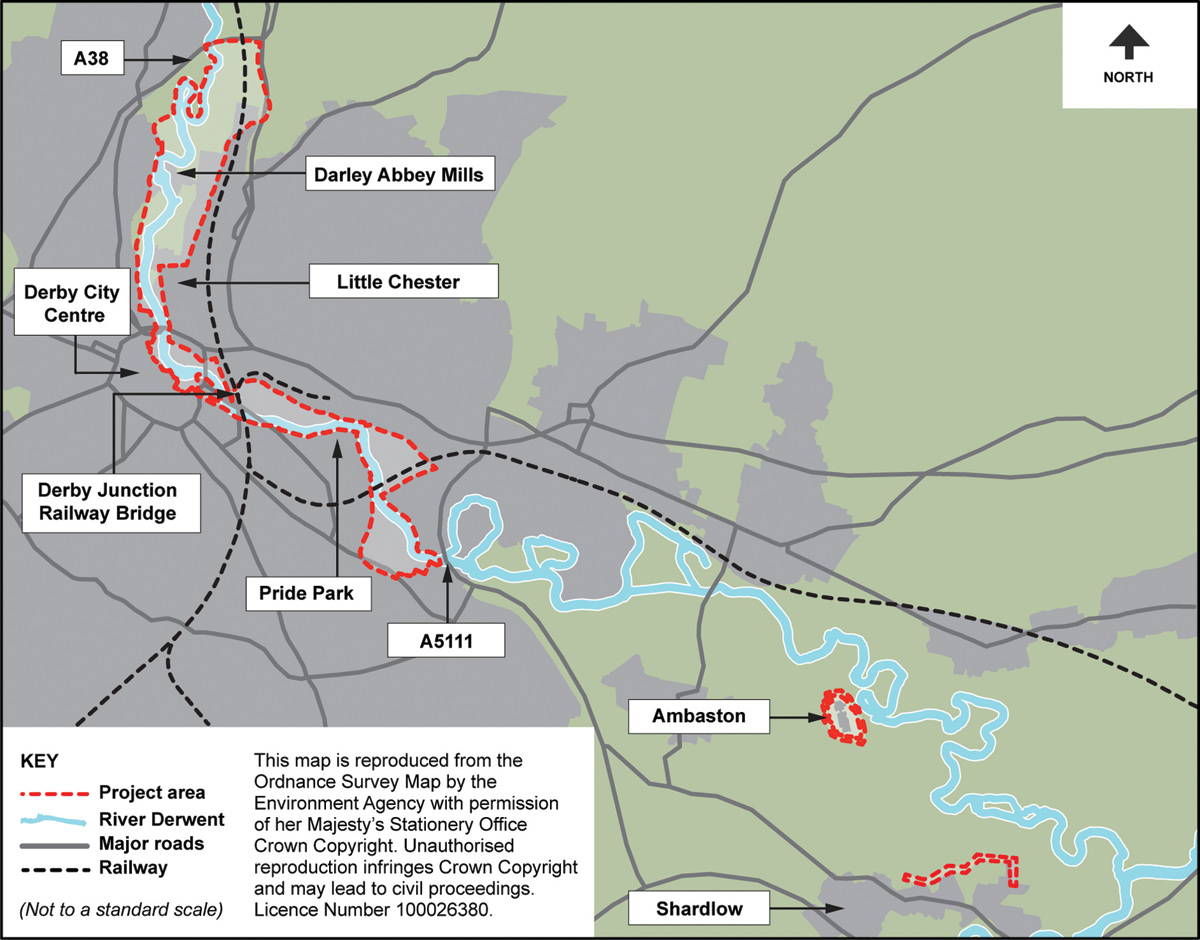

Our approach is characterised by the supply of valves penstocks and actuators to the Birmingham Resilience Project. The business has currently supplied over £4 million of products to the site.

The water treatment works supplies water to 1 million people in Birmingham. It was imperative that in delivering the project the contractors built a works that would be able to operate for years to come to serve the growing population of Birmingham whilst complying with health & safety, environmental and both Severn Trent and industry leading performance standards. Key to achieving this was the quality and efficacy of products chosen by the contractor.

Severn Trent and its contracting partners, Doosan Enpure, NMC and Barhale needed a valve partner that understood the specific performance requirements, had experience in product selection and performance levels to deliver on the scheme’s targets. The Flow Control Group was identified as having the skills and knowledge across the spectrum of valves, penstocks, actuators and auxiliary equipment to achieve this.

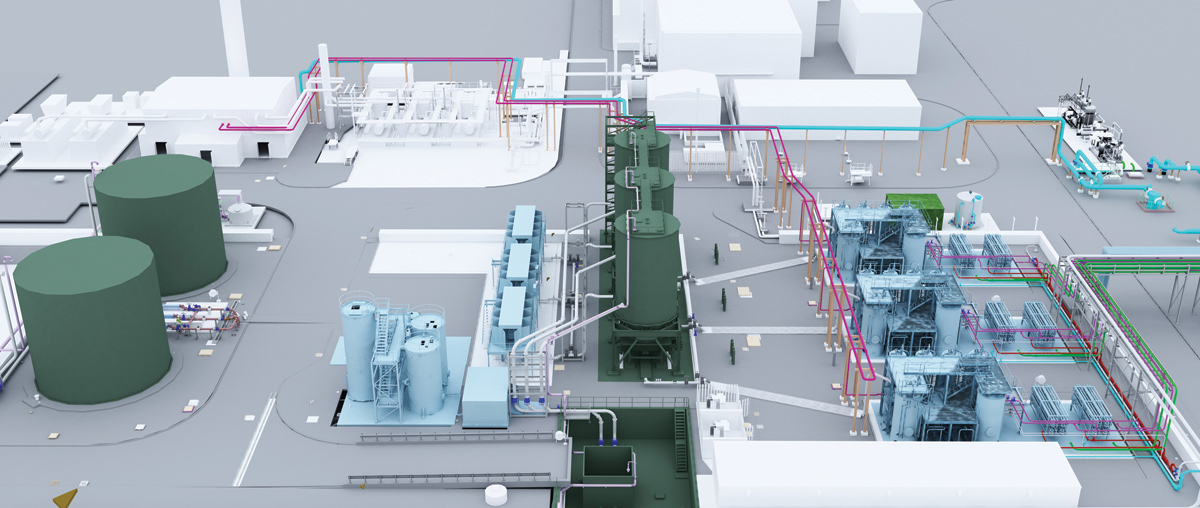

As a specialist valve package supplier Flow Control were able to engage with contractors at design stage to optimise product selection. This led to changes to concept design and enhancements to the performance of the plant. This in turn led to cost savings on initial purchase and to whole life performance costs. In selecting valves and auxiliary equipment we used proprietary sizing software, Inventa design software and experience to select products and to design extension spindles and other auxiliary equipment.

The valves available to contractors are vast but selecting the correct valve for an application involves a detailed understanding of operation characteristics including required operating performance, pressure requirements, flow control characteristics, chemical concentration, treatment performance, pressure and transience. Selecting the correct valve for a requirement required a valve supplier who could assess the correct valve for a particular operation and who had at its disposal the necessary valve sizing, flow control and performance data and programmes necessary to choose the correct valve.

Flow Control have the capabilities to carry out the analysis to select the correct valve. We worked closely with the contractors to design and supply a complete package of valves and actuators including manual and actuated valves which met the performance criteria specified by Severn Trent. This included ancillary equipment including spindles, support brackets, pedestals and headstocks all designed and manufactured in house.

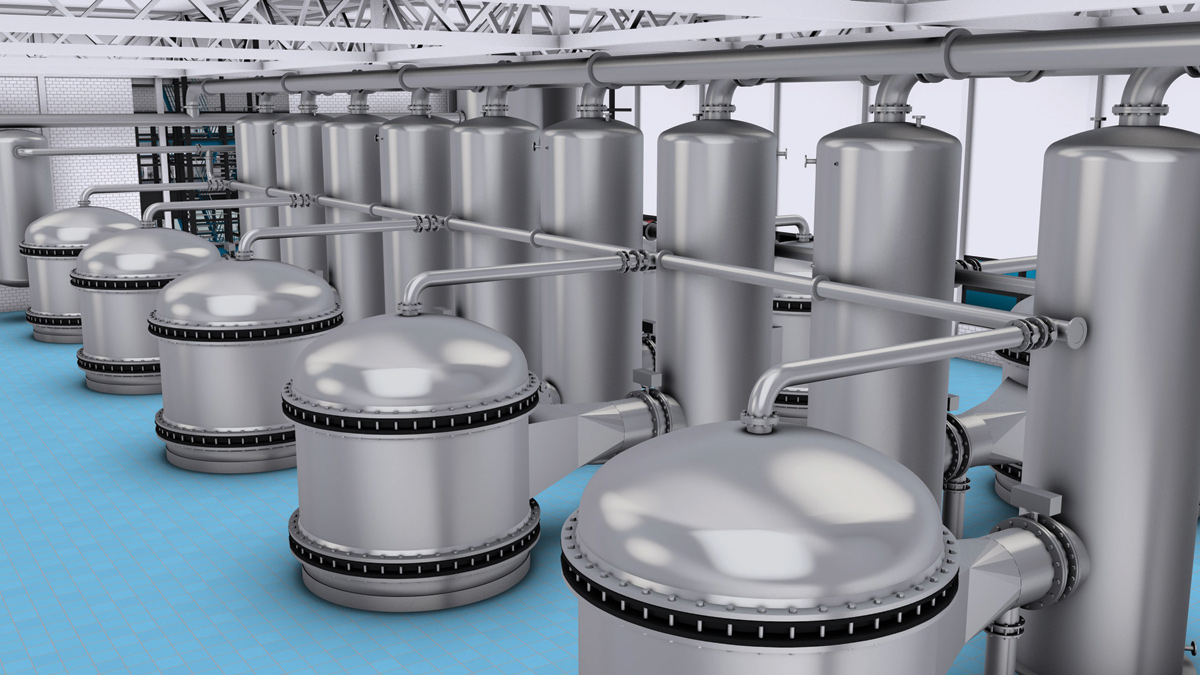

Valves supplied as part of the package included manually operated and actuated valves and included both valves for isolation and flow control. Valves supplied included, gate valves, non return valves, eccentric plug valves, butterfly valves, pinch valves, ball valves, penstocks, stop logs, knife gate valves, air valves.

Air valves supplied included triple function modified air valve for handling low pressures and piped outlets where proprietary software was used to design and select the correct air valve. This included carrying out scenario testing on a purpose built test rig and the production of specific flow graphs based on information provided by the contractor.

In the South Tower an existing part of the plant we were able in conjunction with the contractor to plan a refit of non standard rising spindle valves and design a plan of works using infrared 3 D modelling camera. The use of modular assembly allowed for ease of installation and reduced health and safety hazards and led to cost savings.

Drawing on our experience we were able to offer a full actuation service including actuator sizing and selection with actuators being fitted, set and tested in house for ease of installation on site, saving time and reducing health and safety issues. This included electric Pneumatic and hydraulic actuators.

Auxiliary equipment required to operate the valves included spindles, couplings, universal joints, guide brackets, machined drive bushes, pedestals and headworks. All of these were designed and manufactured in house.

We employ four design engineers with experience of Autocad Inventa and other design software together with FEA software and actuator sizing programmes.

Our site services team were able to carry out full installation commissioning and testing of products and offer confirmation of performance including telemetry to prove functionality against design conclusions.

All valves and auxiliary equipment supplied are manufactured under a quality system to ISO9001 2015, have a design life of 25 years minimum and a standard warranty of 5 years which can be extended on negotiation. The quality system is administered by a quality manager who reports directly to the General Manager. Quality records for every job are maintained and are available for inspection. Full traceability of all products is available and products capable of being identified by tag numbers and cast identification marks.

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Undefined variable $taxonomies in /var/www/wp-wpodev/wp-content/themes/wpo-2023/_templates/ref-item.php on line 9

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301