Aarsleff Ground Engineering Ltd

Stourport Cofferdam

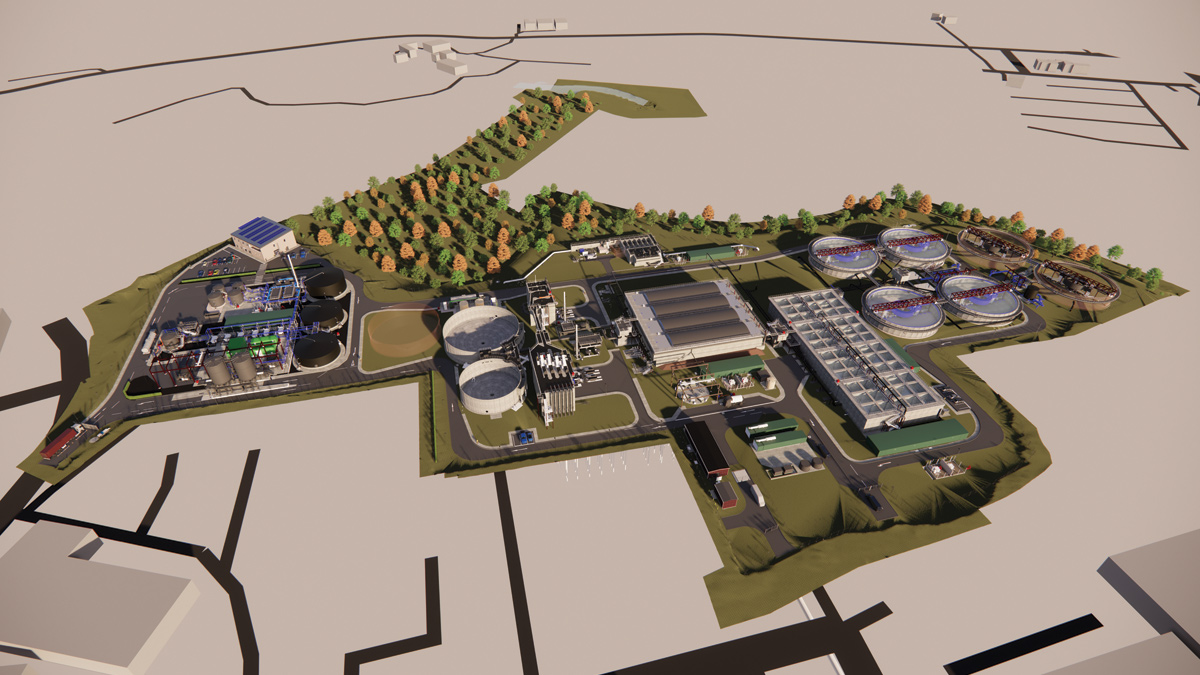

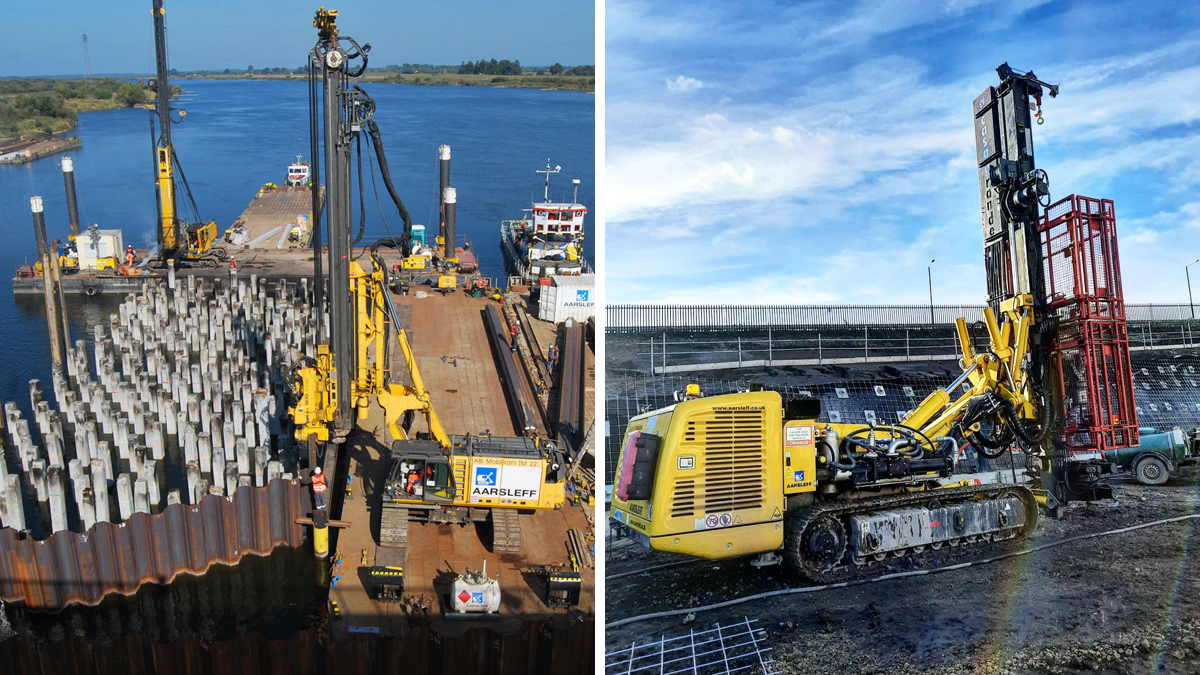

J Murphy Group awarded Aarsleff the contract to install a temporary sheet piled cofferdam on the River Severn, as part of the £300 million Birmingham Resilience Project. The scheme is one of Severn Trent’s largest ever infrastructure projects, specifically to develop an alternative water supply for Birmingham to complement the Elan Valley Aqueduct (EVA). The Birmingham Resilience Project will create a new abstraction point and pumping station on the River Severn, at Lickhill Quarry near Stourport, to which water will then be pumped along a new 25km pipeline, through pipes with a 1.0m diameter, to the water treatment works in Birmingham. Aarsleff’s sheet piling works allowed a dry working area for J Murphy to construct the secant piling to the intake structure. Sheet piles will then be subsequently removed and the entire structure submerged. Water is to be taken from the River Severn which will provide a new source for the aqueduct, while maintenance takes place on the original EVA. When the resilience plan is in operation, the city of Birmingham will be drawing water from at least four sources, rather than just one

Early contractor engagement between J Murphy and Aarsleff identified significant technical deficiencies in the early engineering proposals for the temporary works cofferdam. Aarsleff’s proposed design was safer, quicker and cheaper with significantly less risk to the environment, their clients program and operatives. Aarsleff installed the bespoke temporary sheet piled cofferdam which comprised 154 (No.) AZ26-700 steel sheet piles, with an integral enhanced toe support system comprising of 53 (No.) H-Section piles. These were required due to the very shallow underlying bedrock, which only allowed for a limited sheet pile penetration. Access was provided by a temporary access works platform allowing safe working over water. Aarsleff employed a high frequency vibratory hammer and an impact hammer to drive its piles (using panel driving techniques) and employed a 110-tonne capacity mobile crane operating at a maximum 25m radius to unload and handle piles and hammers.

Senior technical estimator Ashley Carter said:

“This was a technically challenging scheme to be involved with requiring a lateral thinking approach to resolving the challenging problems. The prestigious project demonstrates the high level of experience and expertise Aarsleff’s sheet piling department can offer to its clients”.

Aside from delivering the project on time and within budget, Aarsleff were also able to reduce risk and environmental damage. Risk reduction through application of practical construction methodology, and Reduction in Environmental impact, (as the original scheme involved drilling underwater and spoil flushed directly into the watercourse). Steel sheet piles will also be recovered for re-use making this element of the scheme carbon neutral. Aarsleff Ground Engineering took the technical challenge and applied sense and reason to develop a practical, constructible and engineered solution, which benefitted all parties for the aforementioned Environmental, Commercial and Safety aspects. Meeting a tight construction programme at the front end of a long complex scheme gives Aarsleff great satisfaction.

Scope of works

- 154 (No.) AZ26 steel sheet piles (section modulus 2600cm3/m of max length 8.0m)

- Integral enhanced toe support system comprising of 53 (No.) 254/254/132 S355 JO H-Section piles

- Prefabricated box section connection detailing at 1.26m centre to centre

Construction period

- 21st July 2017 – 13th Sep 2017

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/taxonomy.php on line 3720

Warning: Array to string conversion in /var/www/wp-wpodev/wp-includes/category-template.php on line 1301

Senior Process Engineer (67418BR)

| Location | North East | Durham | Discipline | Project Delivery | Design |

| Contract type | Permanent | Job reference | 67417BR |

| Work pattern | Full-time | Recruiter | Lauren Hutchinson |

| Sector | Water | Wastewater | Interested? | APPLY HERE |

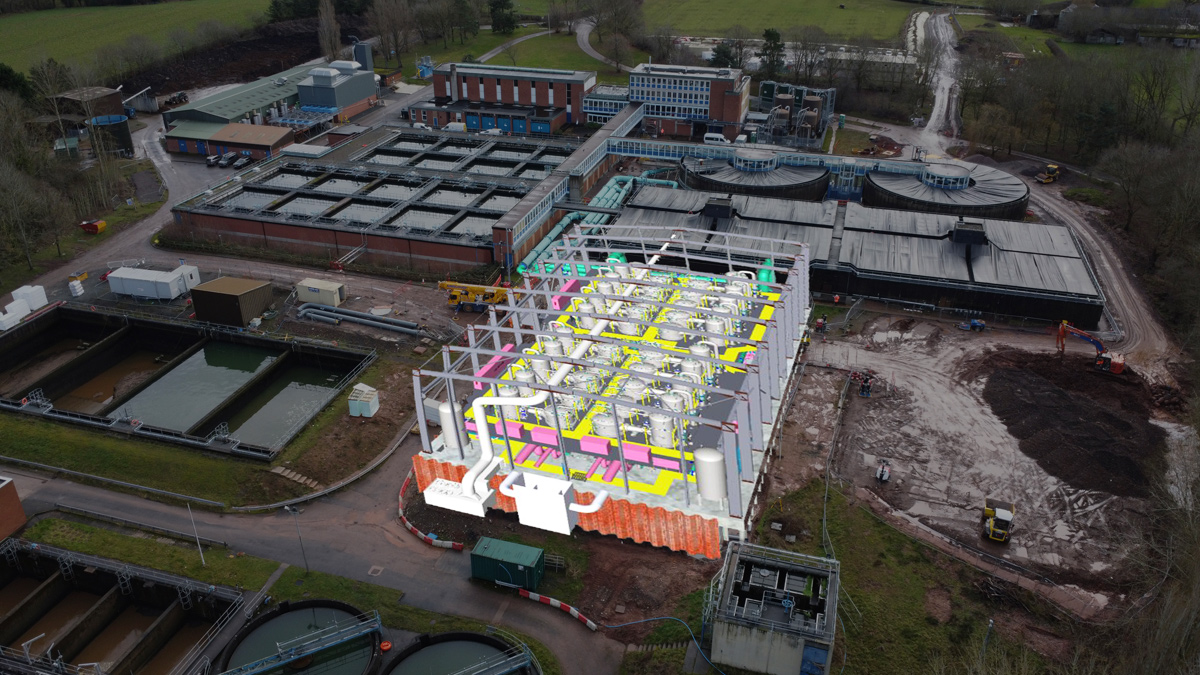

Mott MacDonald Bentley (MMB) is the design and build unit of global engineering consultancy Mott MacDonald. Our Design Leads are responsible for large projects or programmes of work, managing between one and three Project Leaders as well as specialist multi-discipline designers to deliver for our clients.

As a Senior Process Engineer, you will be accountable for the design of a programme of water and wastewater infrastructure and non-infrastructure projects through the outline and detailed design, construction, commissioning, and handover. You will be responsible for building a project team comprised of electrical, mechanical, civil, and process designers who will support your Project Leader. You will provide the direction and co-ordination to enable your project teams to complete the designs in accordance with the specifications, to programme and within budget.

This role will provide you with the opportunity to develop your technical and management skills, grow your professional network, and provide you with excellent long-term potential to advance your career.

Candidate Specification

- Chemical Engineering or relevant Process Engineering related degree, preferably chartered.

- Experience and understanding of water and/or wastewater unit processes and treatment plant, with experience of delivering process design for wastewater projects.

- Experience of HAZOP studies as chair or team member would be advantageous

What we can offer

At Mott MacDonald Bentley you will be offered a competitive salary which is commensurate based on your experience. Our core benefits include:

- Pension matched up to 7%

- Competitive annual leave and the option to purchase additional annual leave

- Life assurance

- Enhanced parental leave

- Annual professional institution subscription costs

- Flexible benefits to suit you, including cycle to work scheme and interest free season ticket loans